Sušička na stříkání Výrobce

-

LPG SPRAY SUSER TAME pro mléko

Vysokorychlostní odstředivá sušička je nový typ procesního zařízení pro sušení s vysokou účinností, může způsobit roztok, emulze, odpruže... -

LPG 5L odstředivá sušička pro kávový mléko

Aplikace: Proces sušení s vysokou účinností pro roztoky, emulze, suspenze a vložení do suchého prášku, jemných nebo středně granulárních ... -

LPG 5L SPRAYSKÉ DUSKER PRO VAGE PRECTER

5L Spray Sceer je nejmenší sušička, může každou hodinu dehydratovat vodu 3-7 kg, vhodnou pro laboratorní použití nebo testování. Sušička ...

Spray Dryer je druh kontinuálního atmosférického tlakového sušičky. Nastříkejte kapalný materiál do mlhy pomocí speciálního vybavení, což mu umožňuje vstoupit do kontaktu s horkým vzduchem a být sušen. Používá se k sušení některých termosenzitivních kapalin, suspenzí a viskózních tekutin, jako je mléko, vejce, taniny a drogy. Používá se také k sušení paliv, meziproduktů, mýdlového prášku a anorganických solí. Je dobrý vhodný pro generování prášku a granulárních pevných produktů z roztoku, mléko, suspenze a kapalné suroviny. Proto je sušení spreje velmi ideálním procesem, když distribuce velikosti částic, zbytková obsah vlhkosti, hromada a tvar částic hotového produktu musí splňovat přesné standardy.

O nás

Čest

-

Čest

Čest -

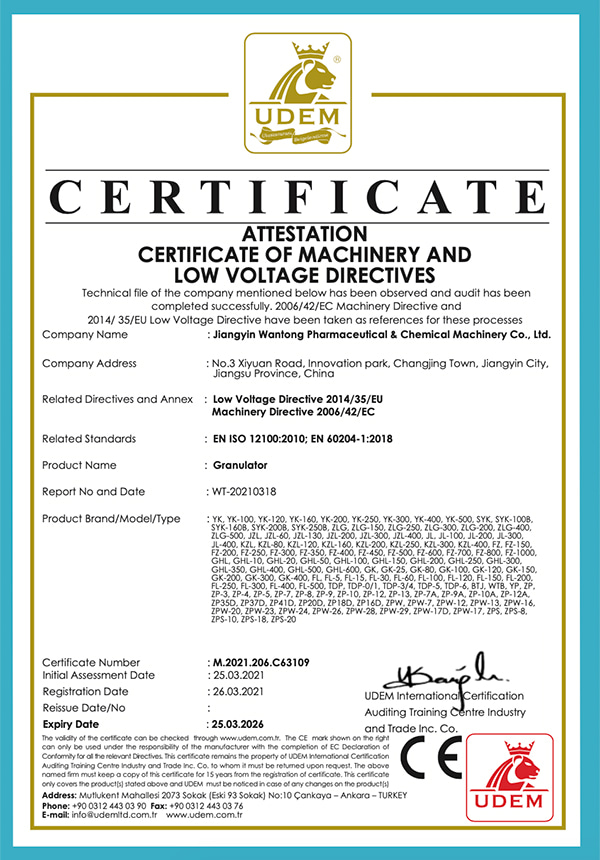

CE

CE

Zprávy

-

Zprávy průmyslu 2026-01-06

Úvod do mlýnků na koření Mlecí stroje na koření jsou nezbytným vybavením jak pro domácí ...

Zobrazit více -

Zprávy průmyslu 2026-01-04

Úvod do průmyslových metod sušení Sušení je kritický proces ve farmaceutické, chemické a potra...

Zobrazit více -

Zprávy průmyslu 2025-12-23

Úvod do Dvoukuželové mixéry Dvoukuželové mixéry jsou široce používané průmyslové míchací...

Zobrazit více -

Zprávy průmyslu 2025-12-18

Úvod do Mlýnky na koření Mlýnky na koření jsou nezbytnými nástroji pro komerční i domácí...

Zobrazit více

Rozšíření znalostí v oboru

What factors influence the efficiency of a spray dryer?

Feed Material Properties:

The characteristics of the feed material, such as its viscosity, surface tension, solids content, and thermal sensitivity, can significantly affect the efficiency of spray drying. Materials with higher viscosity or surface tension may require more energy for atomization and evaporation, while thermally sensitive materials may require lower drying temperatures to prevent degradation.

Atomization Technique:

The atomization method used to convert the liquid feed into droplets can impact the efficiency of spray drying. Different atomization techniques, such as pressure nozzles, rotary atomizers, or centrifugal atomizers, have varying effects on droplet size, distribution, and drying rates.

Drying Parameters:

Factors such as inlet air temperature, air flow rate, residence time, and outlet air humidity play crucial roles in determining the efficiency of spray drying. Optimizing these parameters based on the specific characteristics of the feed material can improve drying efficiency and minimize energy consumption.

Design and Configuration:

The design and configuration of the spray dryer, including the geometry of the drying chamber, the size and shape of the atomization device, and the arrangement of heating elements and air flow patterns, can impact drying efficiency. Well-designed spray dryers with efficient heat and mass transfer mechanisms can enhance overall process efficiency.

Heat Source:

The type and efficiency of the heat source used in the spray dryer, such as steam, gas, or electricity, can influence energy consumption and drying efficiency. Utilizing energy-efficient heating systems and heat recovery techniques can improve overall process efficiency and reduce operating costs.

Particle Collection and Separation:

The efficiency of particle collection and separation systems, such as cyclones, bag filters, or electrostatic precipitators, affects the recovery of dried product and the removal of fine particles from the exhaust air. Optimizing these systems can prevent product losses and minimize environmental emissions.

What are the differences between cocurrent and countercurrent spray drying?

Flow Direction:

In cocurrent spray drying, both the drying air and the atomized feed material flow in the same direction through the drying chamber. This means that the inlet air, carrying the highest moisture content, meets the wettest particles first, progressing towards the dryer outlet.

In countercurrent spray drying, the drying air and the atomized feed material flow in opposite directions. The inlet air, with the lowest moisture content, contacts the wettest particles first and progresses towards the dryer inlet.

Moisture Gradient:

Cocurrent drying typically results in a smaller moisture gradient within the drying chamber compared to countercurrent drying. This means that the moisture content of the particles exiting the dryer is more uniform in cocurrent drying.

Countercurrent drying creates a larger moisture gradient, with the driest air contacting the wettest particles first. This can lead to more efficient moisture removal but may also increase the risk of overdrying or uneven drying of the product.

Temperature Profile:

In cocurrent drying, the temperature profile within the drying chamber gradually decreases from the inlet to the outlet, as the hottest air contacts the wettest particles first. This can help prevent overheating and thermal degradation of sensitive materials.

In countercurrent drying, the temperature profile is typically higher at the inlet and decreases towards the outlet, as the hottest air contacts the driest particles last. This may result in more efficient moisture removal but requires careful control to avoid overheating the product.

Energy Efficiency:

Cocurrent drying generally requires less energy compared to countercurrent drying, as it operates with lower inlet air temperatures and shorter residence times. However, it may not achieve the same level of moisture removal efficiency as countercurrent drying.

Countercurrent drying can be more energy-intensive due to higher inlet air temperatures and longer residence times. However, it can achieve higher moisture removal rates and may be preferred for drying heat-resistant or high-moisture materials.

Product Characteristics:

Cocurrent drying tends to produce products with more uniform moisture content and particle size distribution, making it suitable for heat-sensitive or delicate materials.

Countercurrent drying can result in faster moisture removal and may be preferred for applications where high production rates or low final moisture content are required.